Project: Skyboat

Client : Guangxi Leye Dashiwei Tourism Development Co., Ltd

Architect : Zhong Huaying Studio, Nanjing University

Structural Engineers : XinY & Yuanlizhu

Co-design : LiLi Studio & Shanghai ZhongJian Architectural Design

Principal Contractor : China Railway 25th Group 6th Company

Location : Leye, China

Completed: 2019

Awards:

Golden Winner of A' Awards 2022 (Milan)

Winner of Iconic Awards 2022 (Frankfurt)

Finalist of A+ Awards 2021 (New York)

Media reports:

TRENDS vol37 2c (New Zealand

)

Cover project of Advanced Steel Construction vol17 no1. (Hong kong)

Cover project of IStructE website Nov 2020 (London).

General: Project background and information

Skyboat is a two-storey building consisting of hotel rooms at the ground floor, a café at the first floor and a roof viewing platform which contains a 10metre-by-12.5metre walk-on glass floor. The building comprises a construction area of 495m2 and covers a plan dimension of 10metres by 80metres. Both ends of the building cantilevers out by 34metres and 22metres respectively. The total steel weight used is 438 tonne.

Fig.1 lands on ridge © Yongheng

Fig.2 Over clouds © Li Jin

Fig.3 34-metre front cantilver © Yongheng

Fig.4 22-metre rear cantilever © Yongheng

The project is located in the Karst area in Le Ye County, Guang Xi Province. The seismic intensity scale of the site is set to be 7.

Extreme conditions

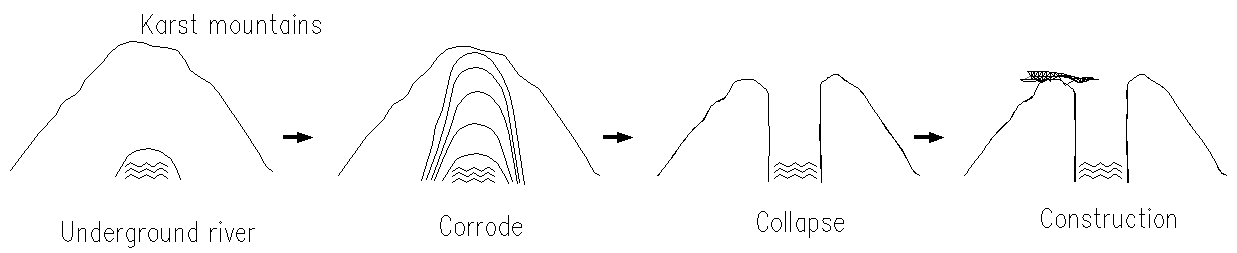

Wahsed by the powerful underground rivers for thousands of years, a 613-metre-deep sinkhole, called Dashiwei Tiankeng, is then formed with vertical walls on all sides.

Fig.4a History and construction ©XinY

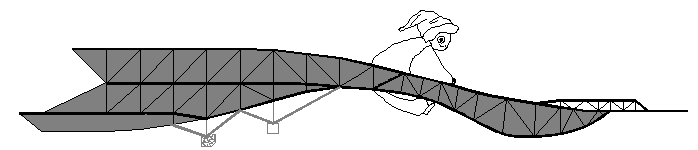

The top of the sinkhole is extremely narrow which can only accommodate a small passageway. Skyboat is proposed to span over the passageway and cantilever out to each side of the mountain ridge. Similar to the tumbler toys, it is proposed to lower the structure centre of gravity and utilize the minimum area (10metres by 30metres), in which way, the self-balance of the structure is therefore achieved.

As the structure cantilevering over the sinkhole, the construction method has to be carefully designed.

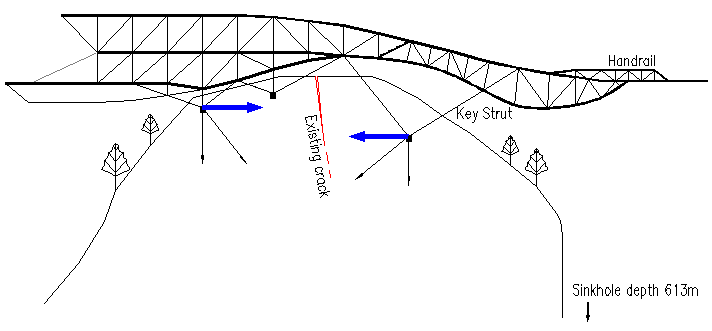

An existing crack, which is circa 10cm wide and several hundred metre long, exists at the top of the ridge. The depth of the crack is unknown. It is therefore an important challenge to keep and even improve the stability of the site.

Creativity and innovation

The 400m long crack at the top of the ridge indicates the site is not stable. Apart from grouting the existing crack, it is also proposed to have the key struts at each ends of the building inclining towards the ridge, the horizontal component forces from which then provided the embracing forces to the ridge and hence improved the stability of the site.

To avoid bearing vertical force destroyed the mountian, the rock under the shadow of the building which has the same weight as the structural self-weight has been removed.

Having the front balustrades as part of the truss structure enables the front cantilever to be as thin and light as possible.

By increasing the key strut lengths, the pre-cambering of the front cantilever structure is then achieved, which can compensate the deflections under the dead loads and some of the live loads. This also protects the glazings from large deformations.

Fig.4b The horizontal component forces from the key struts improving the stability of the site. ©XinY

Sustainability

There are only five supports proposed. This minimizes the damages to the local vegetation. The horizontal component forces from the self-weight of the structure provides the embrace forces to the ridge and helps to stabilize the site.

To protect the local plants and rivers, hanging falsework was used during the construction stage and to have the structural members installed by pieces.

Due to the minimal interface in the local environment, this project has received the Sustainability certificate and awards from local government and sustainability organizations.

Fig.5 Self-support building up without ground stagging © Yongheng

Fig.6 Balustrades as part of the main structural system ©Yongheng

Structural Artistry

The structural system and component arrangements were adapted to the force distribution, perfectly aligned with the elegant architectural geometry.

Fig.7 Elegance and detailing © XinY

Fig.8 613m Depth © Yongheng

Value

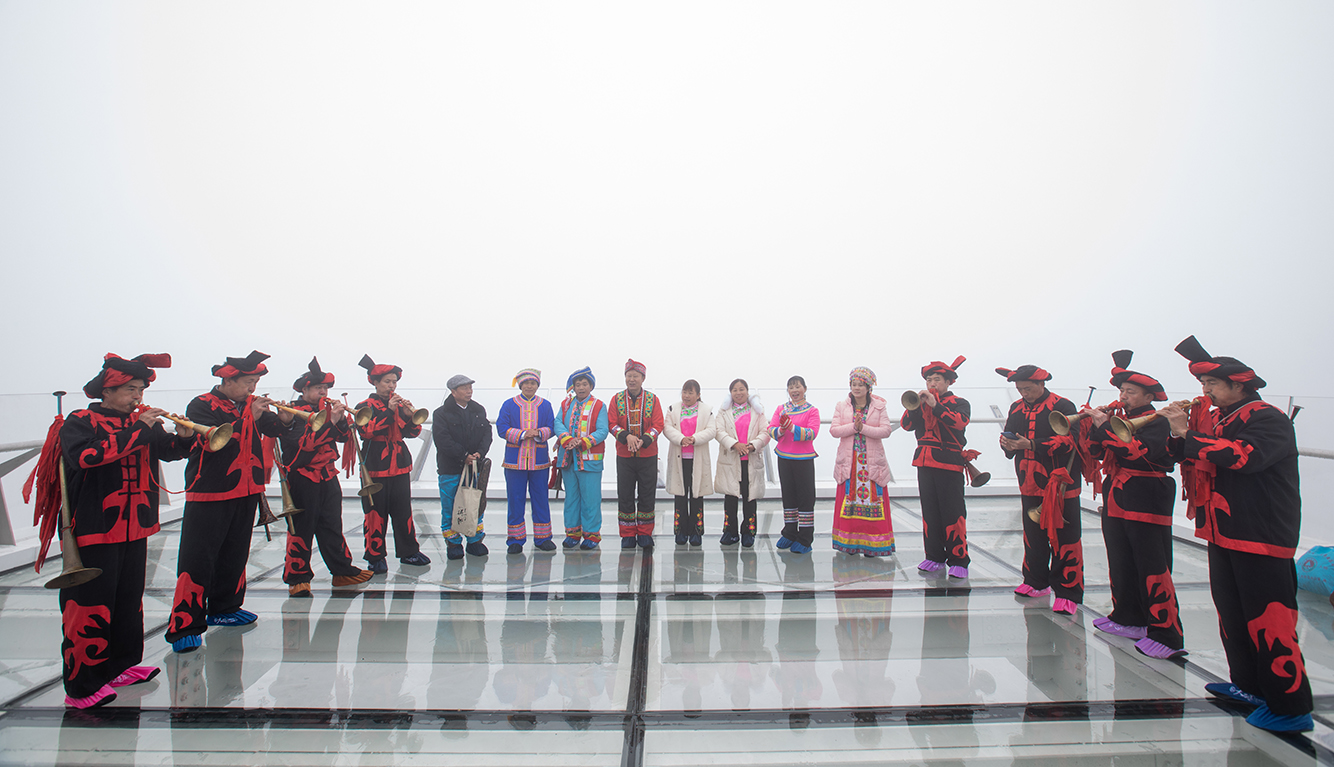

The site is in the poor tribal area of the Zhuang minority. The project succeeded in providing 32 new jobs for the local people.

Fig.9 Local people celebrating ©Yongheng

Fig.10 Indoor © Yongheng

Fig.11 A big goose for children ©XinY

A ‘Niles Big Goose Adventure’ themed event is under organization by the client team, which encourages the children to be brave, to love, to coordinate and to share.

As a landmark project, the construction of Skyboat has attracted thousands of tourists to the resort, supporting the development the local tourism.

Summary

The project is located in the world heritage site, Dashiwei Tiankeng Sinkhole. The rich and unique karst area offers an incredible view of the nature, but also a poor and challenging construction condition. The site is constrained and unstable. The project engineers and the architects were working closely and fully coordinated to find solutions through innovative structural forms to minimize the interface to the environment, improve the stability of the site and achieve an elegant cantilever structure.