Project: Donut

Client : Vanke

Architect : AAI

Structural Engineer: XinY

Co-design : Beiyang

Principal Contractor : Shengshiwei

Curtain Consultant : CAC

Location : Qingdao China

Completed: 2019

Awards:

Winner of the StructuralAwards2020 Showcase (London)

Media reports:

Cover project of Advanced Steel Construction vol17 no2. (HongKong)

General:Project background and information

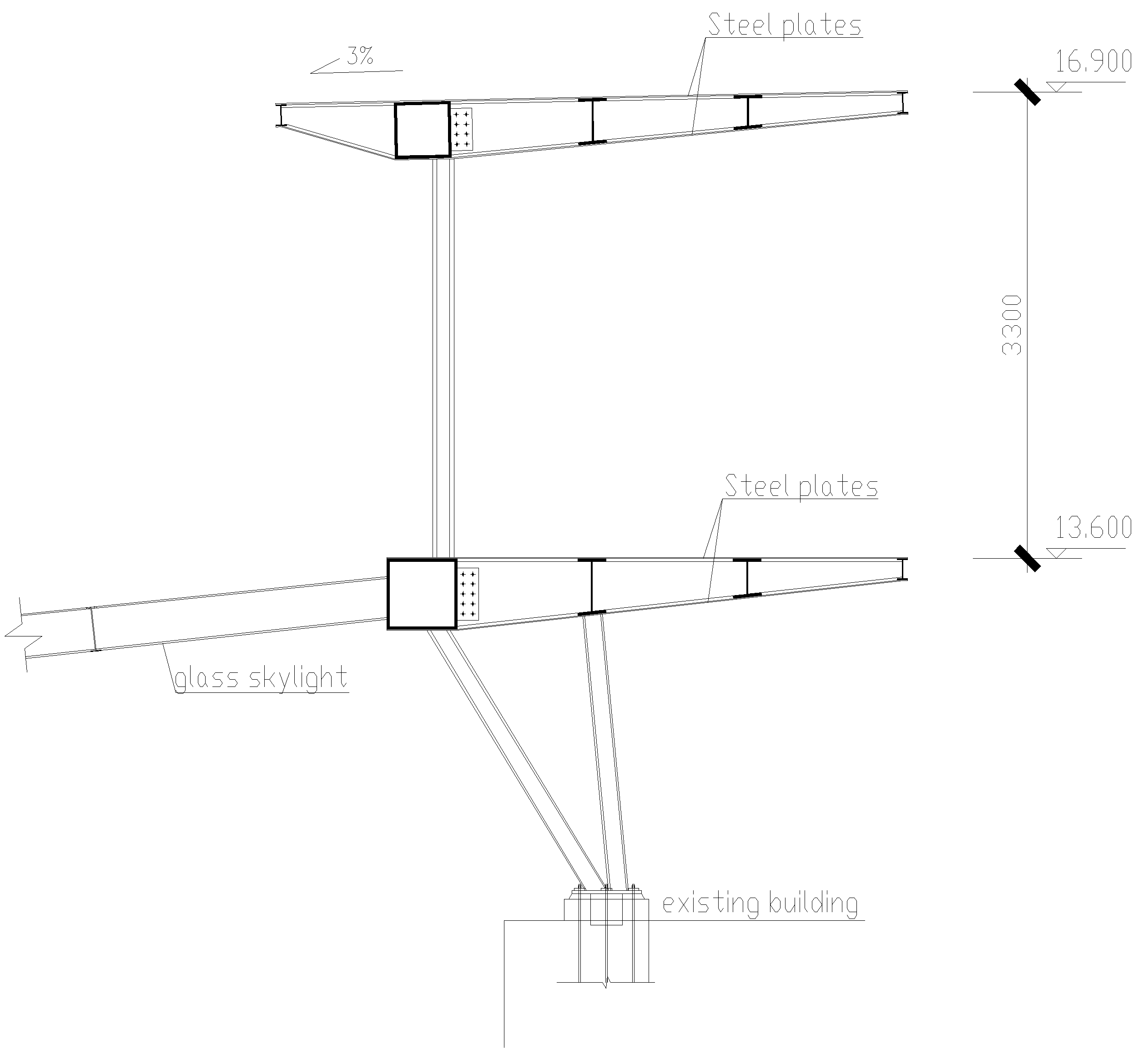

The Donut, located in Huangdao district of Qing Dao city, is a walkway ring floating over the top of three existing buildings. It is 24.5 metres in diameter and 3.4 metres in width, sitting at 13.6 metres above the ground level and covered by a roof at 3.3 metres above. The intenal ring of the Donut is infilled with a glass skylight. The total area of the project is 486 metres square and the total steel used is 146 tonnes.

Fig.1 Top view photo by Yunfei Peng

Fig.2 Perspective view photo by Yunfei Peng

Fig.3 Front view photo by Yunfei Peng

The glass skylight is in an inverted shallow dome shape so that all members can be designed in pure tension forces. The centre of the skylight is left open to improve the wind performance.

Fig.4 Glass skylight photo by Yunfei Peng

Creativity and innovation

The structural stability of the Donut is achieved by a single vertical truss along the internal ring. The natural of the geometry then enables the walkway floor and roof to cantilever from the internal ring truss outwards without any structures along the external ring, providing an unobstructed view to the visitors.

Fig.5 Unilateral support system ©XinY

To achieve sufficient torsional stiffness, all steel beams of the walkway floor and roof are fully welded with steel plates top and bottom to form a large and continuous box section.

Fig.5a Section ©XinY

The Donut has a span of up to 30 metres. To minimise the supporting column sizes, the construction sequence and related connection details are carefully designed to have the loadings applied in steps.

Two of the total eight inclined columns at each end of the 30-metre span are installed after the steel structures and glazing panels are in place. This is to ensure each column to take different loadings at each stage but to have the same movements.

At the column bases of another four inclined columns, internal steel sticks are introduced and welded to the baseplate prior to the installation of the steel structures and glazing panels. Once the permanent loadings are applied to the column internal sticks, external sleeves are then carefully welded so that the end moments due to live loads can be resisted by the stiffer steel sleeves.

Fig.6 Post-welded sleeves ©XinY

Sustainability

The steel plates of the walkway floor and roof have been designed to achieve the structural integrity as well as to provide waterproof barriers. The waterproof test was carried out when welding works were fully completed. It proves that additional waterproof membrane is no longer required and hence a cost saving.

Weathering steel plates are introduced for the walkway floor and roof to save the maintenance cost.

Summary

The aesthetically pleasing structure is an add-on to the local streetscape. It attracts more visitors as well as new customers to the local merchants. It also creates a new acticity space for the local people and hence increases the quality and value of the land.

Fig.7 West view photo by Yunfei Peng

Fig.8 Bird view photo by Yunfei Peng

construction video ©XinY